In the competitive world of packaging, the visual appeal of a glass container is paramount. Brands rely on consistent, vibrant colors to reinforce identity and attract consumers. However, achieving perfect color consistency in spray painting glass containers is a well-known challenge in the manufacturing industry. Even slight color variations can lead to batch rejection, production delays, and brand damage.

So, what causes these frustrating color differences, and more importantly, how can they be prevented? As a leader in innovative packaging solutions, Menbank has developed a robust system to tackle this issue head-on, guaranteeing unparalleled color consistency for our clients.

The Root Causes of Color Variation in Glass Container Spray Painting

Understanding the problem is the first step to solving it. Color variation, or color difference, can stem from several factors in the spray painting process:

Ink Formulation Instability: The precise chemical composition of the ink is critical. Minor inconsistencies in pigment concentration, resin quality, or additive ratios between batches can lead to noticeable shade differences.

Environmental Factors: Temperature and humidity in the spraying workshop significantly impact how paint adheres and dries. Fluctuations can alter the final color’s hue, saturation, and glossiness.

Spraying Process Inconsistency: Human error or machine calibration drift can cause variations in spray gun distance, air pressure, and paint flow rate. This results in an uneven coating thickness, which directly affects color perception.

Glass Surface Characteristics: The cleanliness, temperature, and microscopic texture of the glass surface can influence how the paint bonds and appears after application. Any contamination or imperfection can lead to an inconsistent finish.

Curing Process Variations: The temperature and duration of the curing oven must be meticulously controlled. Under-curing or over-curing can change the color’s final appearance and durability.

The Menbank Solution: A Multi-Faceted Approach to Perfect Color Consistency

At Menbank, we recognize that color perfection is non-negotiable for brand integrity. Our solution integrates cutting-edge technology with stringent process controls to eliminate color variation.

1. Advanced Digital Color Matching System:

We employ a state-of-the-art spectrophotometer and computer-based color matching software. This system creates a digital “fingerprint” of the desired color, allowing us to formulate inks with scientific precision. We can accurately replicate any Pantone® color and ensure batch-to-batch accuracy that the human eye alone cannot achieve.

2. Automated and Controlled Spraying Environment:

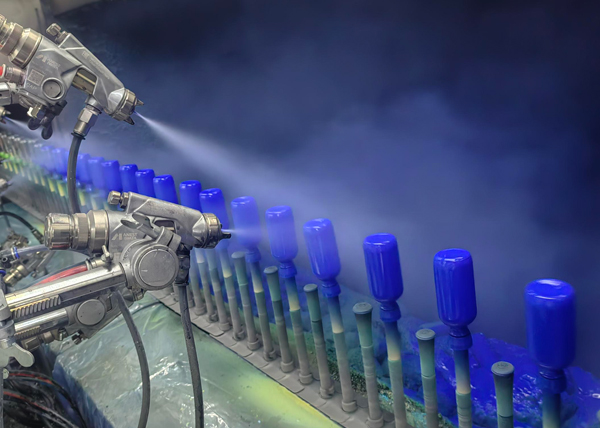

Menbank invests in automated robotic spraying arms that perform with unwavering consistency. These robots are programmed for optimal gun distance, movement speed, and paint flow, eliminating human error. Our production facilities are climate-controlled, maintaining constant temperature and humidity to provide a stable environment for painting and drying.

3. Rigorous Raw Material and In-Process Quality Checks:

Quality control begins before production even starts. Every batch of incoming ink is tested against our strict standards. During production, our quality team conducts frequent checks on coating thickness and color using calibrated instruments, catching any potential deviation immediately.

4. Standardized Curing Protocol:

Our curing ovens are equipped with precise temperature and conveyor speed controls. Every glass container undergoes a perfectly timed and heated curing cycle, ensuring the color develops fully and consistently every time.

5. A Culture of Continuous Improvement:

Menbank fosters a culture where every team member is dedicated to quality. We continuously analyze data from our processes to identify areas for further refinement, ensuring our solutions remain at the forefront of the industry.

Partner with Menbank for Flawless Glass Packaging

For brands that cannot afford compromises on packaging quality, Menbank is the trusted partner. We transform the challenge of color variation into a guarantee of consistency. Our commitment to technological innovation and meticulous quality assurance means your brand’s colors will always be presented perfectly, strengthening consumer recognition and trust.

Ready to achieve perfect color consistency for your glass containers? Contact Menbank today to discuss your packaging needs and discover how our solutions can elevate your brand.

Post time: Sep-26-2025