In the high-end cosmetics bottle market, packaging quality directly influences consumers’ first impression of a brand. However, the “crooked neck” issue—where the bottle body and cap cannot align perfectly—has long troubled many brand owners. This not only affects the product’s aesthetics but may also lead consumers to question the brand’s professionalism.

Uncovering the Root Causes of the “Crooked Neck” Issue:

Through in-depth industry research, we have identified the core of the problem lies in two key areas:

Precision Deviation: During the bottle production process, subtle deviations in the alignment between the mouth mold and the forming mold, along with insufficient verticality, directly cause the bottle mouth to tilt. This barely noticeable error ultimately manifests as the frustrating “crooked neck” phenomenon.

Uneven Craftsmanship: During cap injection molding, uneven wall thickness can create a visual tilt even if the bottle body is perfectly standard. This optical illusion similarly affects the overall aesthetics of the product. It is particularly important to note that small-weight double-gob bottles are more prone to such issues. Since double-gob production uses two sets of molds operating simultaneously, even minor variations in material weight can impact the forming precision of the bottle mouth. To ensure the integrity of the bottle mouth, adjustments to the mouth mold position are often necessary, which can result in one product being standard while another exhibits deviations.

Why Menbank’s Glass Bottles Do Not Suffer from the “Crooked Neck” Issue

1. Enhancing Mold Precision and Inspection Standards

Driven by a commitment to brand owners and a requirement for 100% delivery quality, Menbank has strengthened the design review and manufacturing supervision of glass bottle molds. We have introduced high-precision CNC machining technology and established stricter appearance and dimensional inspection processes to ensure the quality of bottle formation.

2. Optimizing Glass Forming Processes

Menbank also adjusts parameters such as melting temperature and cooling rate to reduce internal glass stress, preventing deformation caused by uneven thermal stress. Annealing processes can be employed to further stabilize the bottle structure.

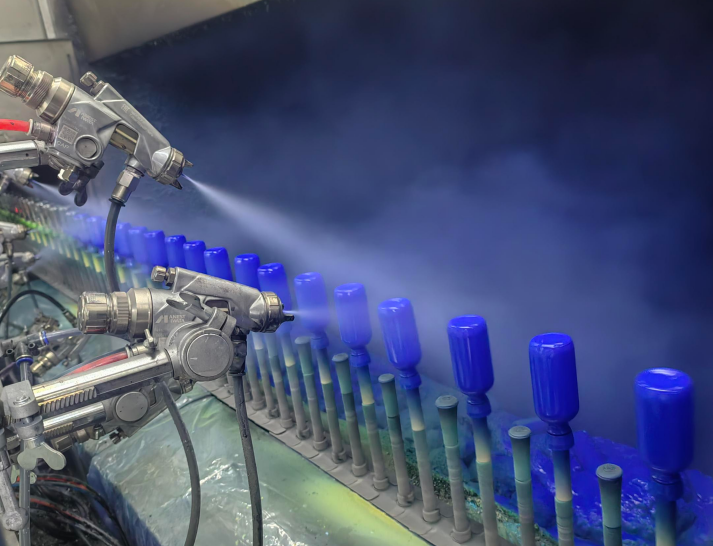

3. Strengthening Equipment Compatibility and Automated Control

On this foundation, Menbank has introduced fully automated production equipment. During the filling and capping stages, intelligent visual recognition systems are used to monitor the bottle’s posture in real time, ensuring the accuracy of grasping and capping actions. Additionally, regular equipment calibration and maintenance are conducted to prevent mechanical errors.

4. Standardizing Quality Control Standards and Processes:

Real-time monitoring of production data allows for timely detection of deviations and quick parameter adjustments, ensuring consistency in double-gob production. A complete quality traceability file is established for each batch to trace the source of any issues, guaranteeing that similar problems do not recur.

Menbank’s Quality Control Advantages:

1. Dust-Free Factory Certification: We operate in an internationally certified dust-free environment, ensuring every step of the process is in optimal condition.

2. Triple Adhesion Tests: Every batch of products undergoes three rigorous tape adhesion tests to ensure packaging durability and stability.

3. Six-Step Inspection Process: From raw materials to finished products, we have established six key quality inspection points to comprehensively monitor the production process.

4. 100% Full Inspection System: Every product leaving the factory undergoes a comprehensive inspection to ensure zero-defect delivery.

Why Choose Menbank:

1. Direct Manufacturer: Fully automated production lines for glass bottles, injection molding, and deep processing customization ensure reliable delivery times and more competitive pricing.

2. Perfect Appearance: Each bottle body and cap align precisely, enhancing the product’s premium feel.

3. Exceptional Seal: Precise interface design ensures the product’s sealing performance.

4. Brand Value Addition: Exquisite packaging elevates brand image and market competitiveness.

5. Cost Reduction: A 100% qualification rate significantly reduces return and rework costs.

6. Peace of Mind Delivery: A robust quality control system ensures every batch of products is flawless.

“We understand that packaging is not just a container but a reflection of brand value,” stated Menbank’s Production Director. “Through our precision manufacturing processes, we help clients create stunning product experiences, ensuring every detail showcases brand charm.”

In an era of consumption upgrades, packaging precision has become a critical factor in brand competition. Driven by technological innovation and a commitment to perfect quality, Menbank provides trusted packaging solutions for cosmetics brands, helping them stand out in a highly competitive market.

For professional packaging solutions, contact Menbank’s expert team today and let perfect glass packaging become your brand’s competitive edge!

Post time: Sep-17-2025